Roundness Profile Measuring Machine

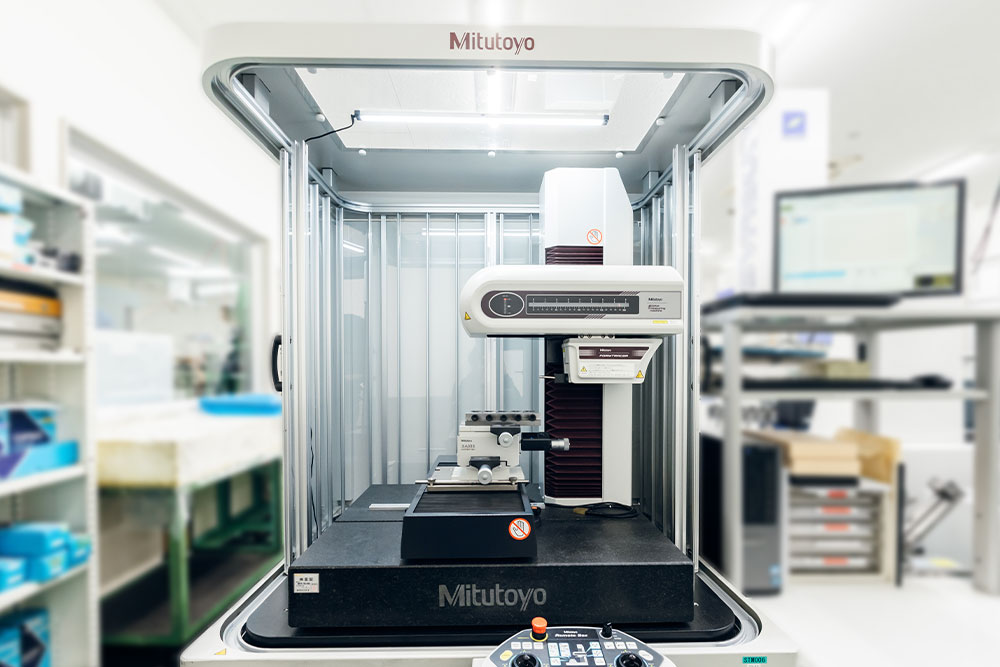

Contact CNC Coordinate Measuring Machine

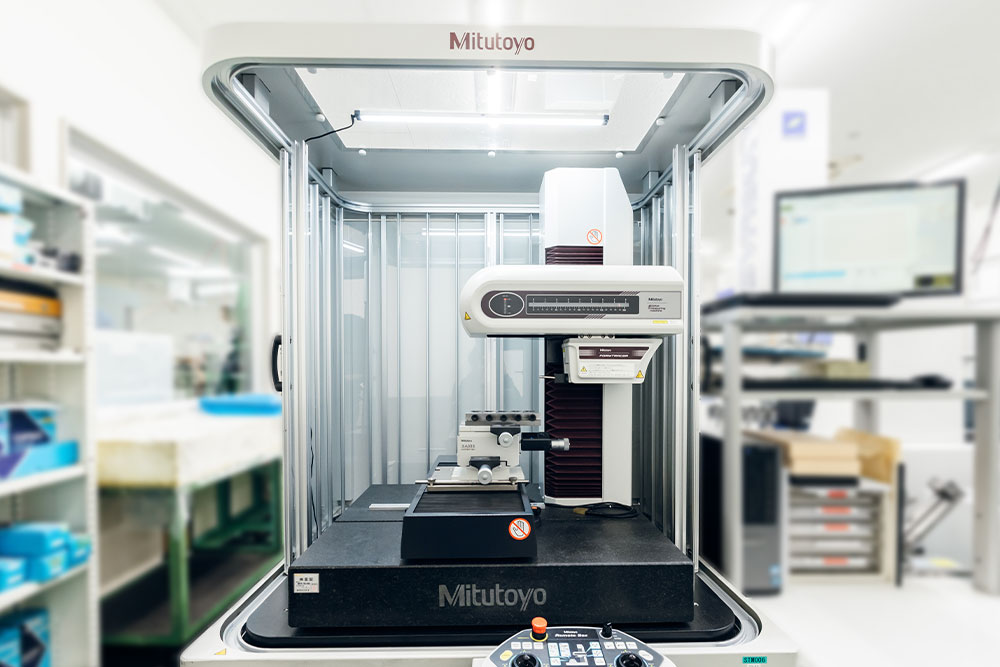

Non-Contact CNC Coordinate Measuring Machine

Roundness Profile Measuring Machine

Contact CNC Coordinate Measuring Machine

Non-Contact CNC Coordinate Measuring Machine

| Equipment | Manufacturer | Model | Specs | Units |

| Coordinate Measuring Machine | Mitutoyo | Crysta-Plus M544 | 500x400x400 | 1 |

| Coordinate Measuring Machine | Mitutoyo | Crysta-Plus M574 | 500x700x400 | 2 |

| Coordinate Measuring Machine | Tokyo Seimitsu | SVA 800A | 800x500x450 | 1 |

| Coordinate Measuring Machine | Tokyo Seimitsu | SVA NEX 7/5/5 | 650x500x450 | 1 |

| Coordinate Measuring Machine | Tokyo Seimitsu | CONTURA 7/7/6 | 700x700x600 | 1 |

| Multisensor Measuring Machine | Tokyo Seimitsu | O-INSPECT543 | 500 x 400 x 300 mm3 | 1 |

| Roundness Measuring Machine | Tokyo Seimitsu | RONDCOM 65A | Φ580×900 | 1 |

| Roundness Measuring Machine | Mitutoyo | RA-400 | Circular/Cylindrical | 1 |

| Roundness Measuring Machine | TAYLOR HOBSON | Talyrond 585HS Pro | Circular/Cylindrical,Vertical500mm | 1 |

| Shape Roughness Measuring Machine | Mitutoyo | CS-H5000CNC | X200mm×Z12000μm | 1 |

| Shape Roughness Measuring Machine | Tokyo Seimitsu | SURFCOM1800D-22 | Surface Roughness 800 x 100 Contour Shape 50 x 100 | 1 |

| Non-contact surface roughness and shape measuring machine | Tokyo Seimitsu | Opt-scope S+model | Motorized XY Stage Travel Range 25x25mm | 1 |

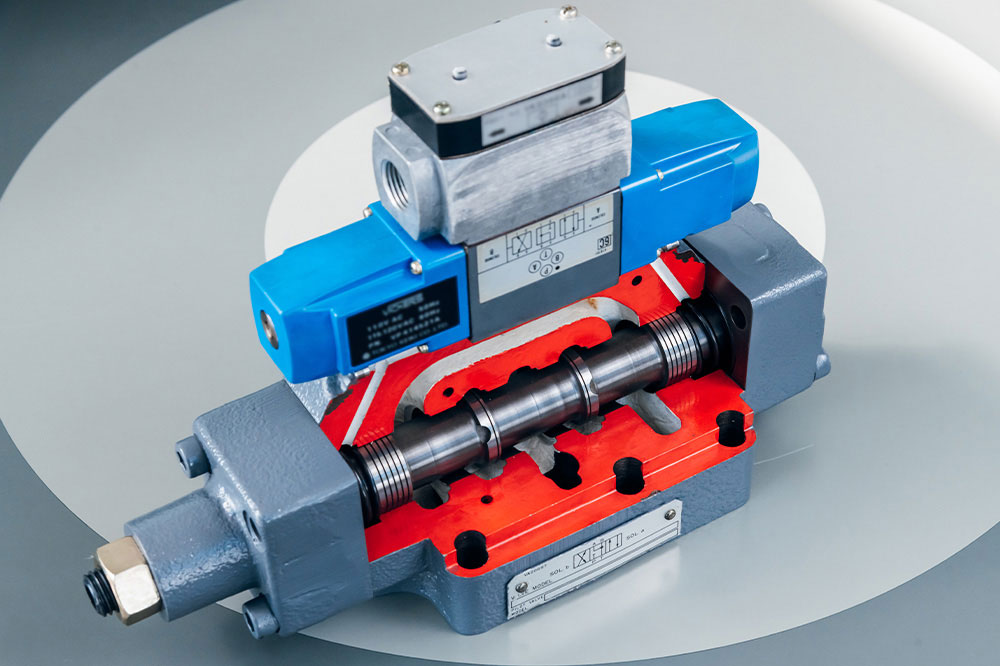

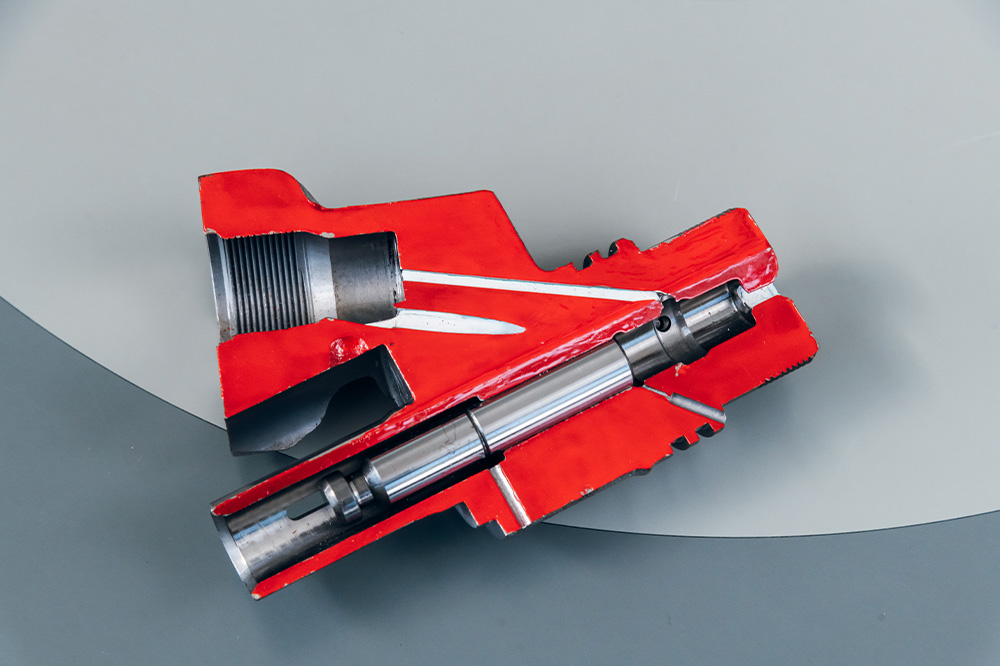

| Hydraulic test stand | TOKYO KEIKI | - | 21MPa,25MPa,34MPa | 1 |

| Hydraulic test stand | RIKEN | - | 200MPa | 1 |

| Hydraulic test stand | Funaki Engineering | - | 30MPa,250MPa | 7 |

| Magnetic Particle Inspection Equipment | Nihon Denji Sokki | NQ-40TS | NAS410 ASTM E1444 | 2 |

| Metallographic Examination Device | Struers | Cutting, Embedding, Polishing | - | 1 |

| X-ray Composition Analysis Device | Olympus | VMR-CCC-A3-J-JA | - | 1 |

| Cleanliness Inspection Equipment | - | Electronic balance/other sets | - | 3 |

| Cleanliness Inspection Equipment | - | Particle Counter | - | 1 |

| Rockwell Hardness Tester | AKASHI | - | HRa,HRb,HRc | 1 |

| Rockwell Hardness Tester | MISAWA SEIKI SEISAKUSHO | - | HRa,HRb,HRc | 1 |

| Rockwell Superficial Hardness Tester | AKASHI | - | HR15N,HR30N,HR45N | 1 |

| Vickers Hardness Tester | AKASHI | - | - | 1 |